TABLET GRANULATION

Our machines processes powders into granules for tablet compression. Components include a granulation chamber, wet granulator, dryer, and final sizing unit.

Fluid Bed Dryer (FBD)

Description

The Fluid Bed Dryer offers a comprehensible solution to the drying of wet granules/powder.

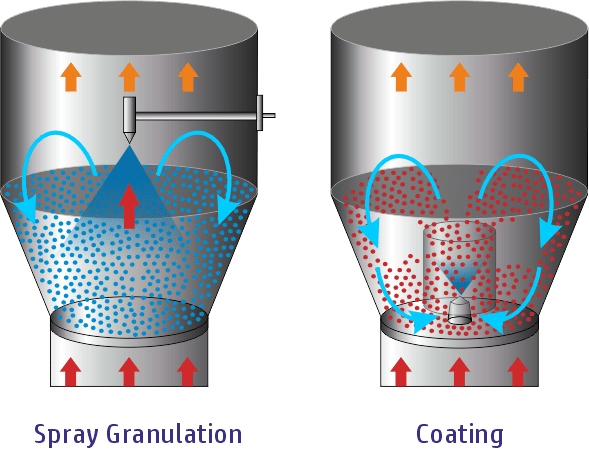

It utilizes the principle of passing the hot air at a high velocity through the bed of the material to be dried; whilst making it fluidized. The blower situated on the exhaust side of the dryer creates the negative pressure which creates the induced draught and sucks in the fresh air which is filtered through a 5/20 micron filter bag into the FBD.

Drying

Wet granules are dried by passing hot filtered air through the product at controlled velocity and volume. A fluidized bed thus exposes maximum product to hot air which quickly removes moisture for uniform and quick drying.

Features

- – cGMP Model

- – Capacity: from 5

- – KGs to 500 Kgs

- – Uniform Drying with less Drying time

- – Efficient in terms of saving energy & time

- – Easy Dismantling of Dutch Sieve & Perforated Sheet at the Product container

- – Provision of an Online Sampling Device

- – Fully Automatic Operation through PLC (Optional)

- – Product Container with Stirrer (Optional)

- – Flameproof Design (Optional)

- – All contact parts are SS 316 / 316 L & Non-contact/cladded Parts in SS 304

- – Documentation: DQ, IQ & OQ will be provided on request

Rapid Mixer Granulator (RMG)

Description

The Rapid Mixer Granulator which is also known as High Shear Mixer Granulator is a multi-purpose processor equally suitable for high speed dispersion of dry powders, aqueous or solvent granulations, and effervescent products and melts palletisation.

In RMG Mixing and wet granulation process is performed in one sequence. The fast moving mixer blades having special angles enforce the powder material into spiral fluidization at the bowl base. The vortex in the material provides faster and uniform distribution of the ingredients.

Features

- – cGMP Model

- – Working Capacity: Models are available with 3 L to 800 L

- – Fully automatic operation based on PLC control

- – Better productivity with less mixing time

- – All Contact parts are SS 316 / 316L & Non-contact Parts are made in SS 304

- – Highly Uniform mixing & granulation

- – Requires less manpower & more hygienic

- – High-Quality Motors which provide better efficiency and save energy

- – Documentation: DQ, IQ & OQ will be provided on request

Auto Coater

Description

The Coater has been designed to carry out most perfect and uniform coating with the least intervention by the operator. ANVAY Auto Coater is designed as a free standing, totally enclosed unit, with inbuilt WIP system. The sides, back & front doors are provided for easy cleaning and maintenance.

Features

- – Completely Automatic

- – Highly Uniform Coating

- – Minimum Process Time

- – Minimum Operator Intervention

- – Quick Changeover

- – Easy to Clean

Pan Coater

Description

The coater is a device employed in the production of pharmaceutical items to apply a protective film, either aqueous or organic, onto a tablet. This film safeguards the tablets from both physical and chemical harm. The key features of this equipment consist of a semi-ellipsoidal pan equipped with a round cover, aiding in the loading and unloading of tablets. Powered by a motor and gear, the pan rotates during the coating process.

Features

- – cGMP Model, available in 12”, 24”, 36”, 48”& 72” size

- – Thermostat provided for easy selection of required temperature

- – All contact parts are SS 316 / 316 L & Non-contact/cladded Parts in SS 304

- – Sanitary design of pan

- – Excellent tablet rolling welded baffle. Detachable baffles are also available on request.

- – Spraying system with Peristaltic pump and solution tank. (Optional).

- – Effective Coating of tablets.

- – Adjustable interchangeable angle of Pan with Higher to lower capacity

- – Documentation: DQ, IQ & OQ will be provided on request