OINTMENT CREAM

Our advanced machinery features include stainless-steel construction, automated dosing, mixing capabilities, and precise temperature control.

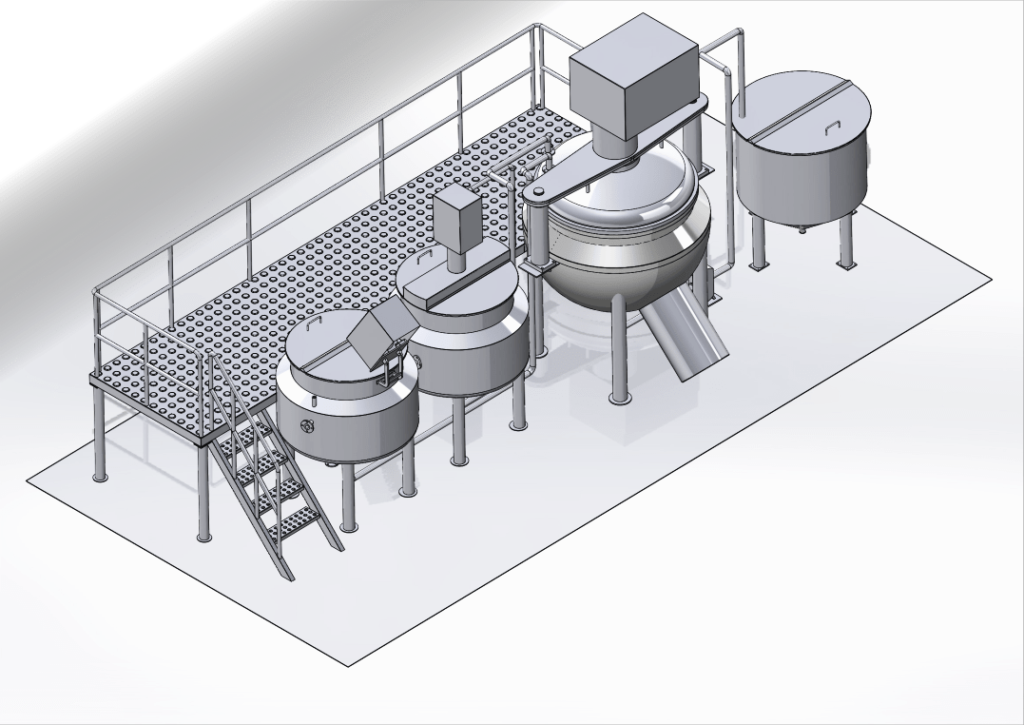

Ointment Manufacturing Plant

Description

Ointment manufacturing plant finds its application in the various fields viz. in Pharma field for creams, gels, sterile and non- sterile & biotech products too and in Cosmetic field for cold creams, hair dye creams, conditioners, lotions gels, shampoo & tooth paste etc. This manufacturing has three main sections viz Main Vessel, wax vessel & water vessel.

The Ointment manufacturing plant comes with many features such as Semi Contra Type Anchor with fix anchor; Small Anchor with gear motor for wax phase vessel; All Pipeline are electro polished from inside, Bottom entry specially designed Homogenizer provided with double mechanical seal ,with cooling system & safety switch operated by control panel choices for anchor design.

Features

- – cGMP Model

- – Capacity: 5 KGs to 3000 KGs

- – Mixing, dispersing, and homogenizing in one operation

- – Homogenous product consistency without trapped air bubbles

- – Large variety of products due to the highly flexible dispersing and homogenizing system

- – Fast product change over

- – High capacity with a minimal space requirement

- – CE certification will be provided on request

- – Documentation: DQ, IQ & OQ will be provided on request

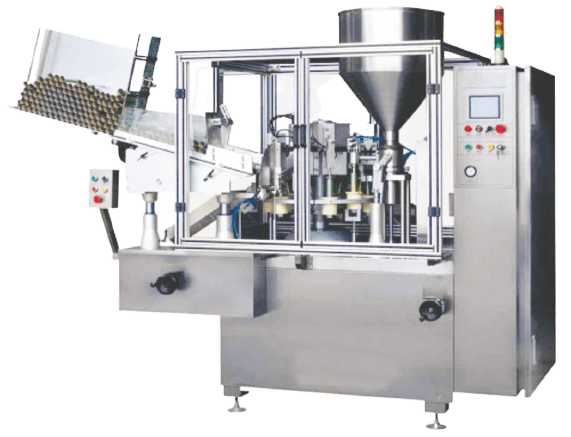

Tube Filling Machine

Description

Automatic Tube Fillers are designed and engineered to produce outstanding quality and precision tube filling and sealing of, plastic, metal-plastic laminate & aluminum laminate tubes with an output of up to 75 tubes per minute. This machine is widely used in the Pharmaceutical, Food, Household Chemical, and Cosmetic industries.

These tube-filling machines operate in an automatic process and are capable of filling tubes of diverse sizes. The ointment filling tools manufactured by us also offer superior performance while filling ointments and creams. Moreover, all the parts of our toothpaste filling devices are SS 316 compliant and adhere to the GMP quality standards.

Features

- – cGMP Model

- – Both Automatic & Semi-automatic machines

- – Automatic tube infeed cassette system

- – Automatic tube cleaning system

- – Both side batch coating system

- – Cap tightening system

- – Tubular cover Aluminium or SS 304 with Acrylic or Polycarbonate housing Jacketed Hopper with Product Stirring Device

- – Reverse / Saddle folding on Aluminium

- – Multicolour filling system

- – Designer sealing pattern

- – PLC based machine operations

- – Before and after filling nitrogen pursing

- – Mechanical tail-free attach filling device

- – Documentation: DQ, IQ & OQ will be provided on request