LIQUID ORAL

We manufacture premium liquid oral dilution devices with automated functions and user-friendly controls that can handle a range of viscosities and bottle sizes.

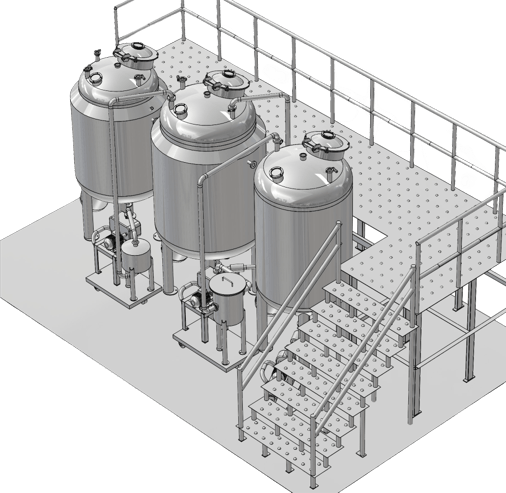

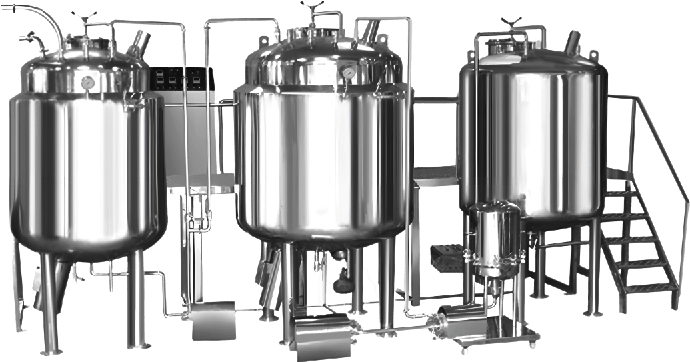

Liquid Manufacturing Plant

Description

The complete plant consists of a sugar melting vessel, a main syrup manufacturing vessel & storage vessel, and allied equipment like filter presses and pumps. It is offered with a bottom entry stirrer or top entry stirrer depending on the customer’s requirement. Externally placed inline homogenizer ensures the entire material homogenization and gives the option for desired multiple passes in recirculation mode with a self-inbuilt pumping facility within the unit.

Features

- – cGMP Model

- – Capacity: 500 Litres to 10,000 Litres

- – All material transfers are done by vacuum or by transfer pumps

- – The entry of the stirrer & high-speed emulsifier is from the top. In-line Emulsifier (as per customer choice) provided on demand

- – All vessels are suitable for internal pressure of 1 Kg. / Sq. cm. and hence can be sterilized

- – All pipes, pipe fittings, and valves are of SS304 / SS316 (as per customer requirement) seamless quality, internally electro-polished, with tri-clover ended joints

- – Documentation: DQ, IQ & OQ will be provided on request